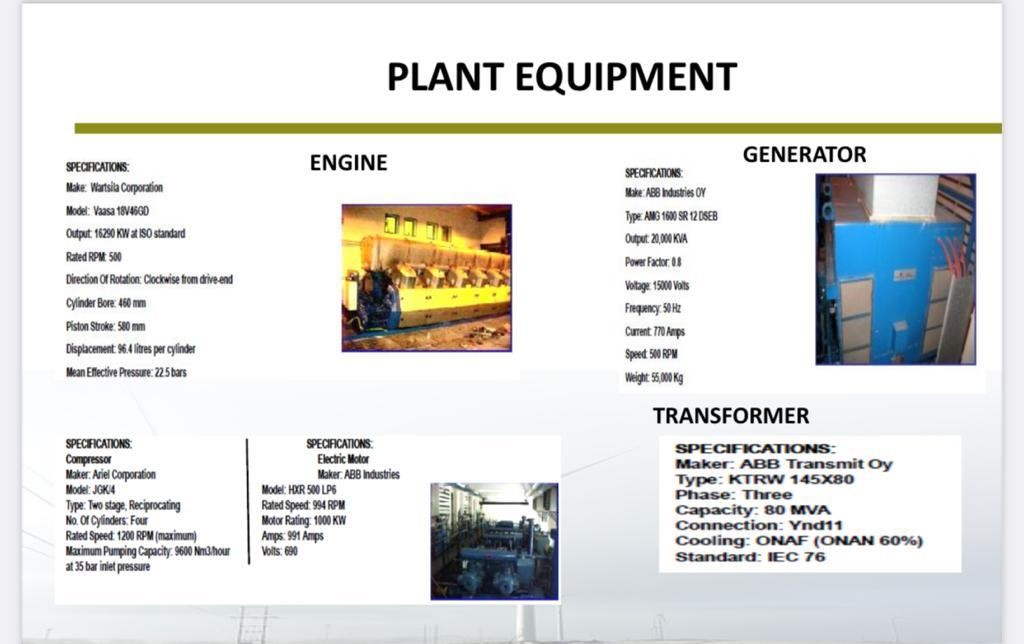

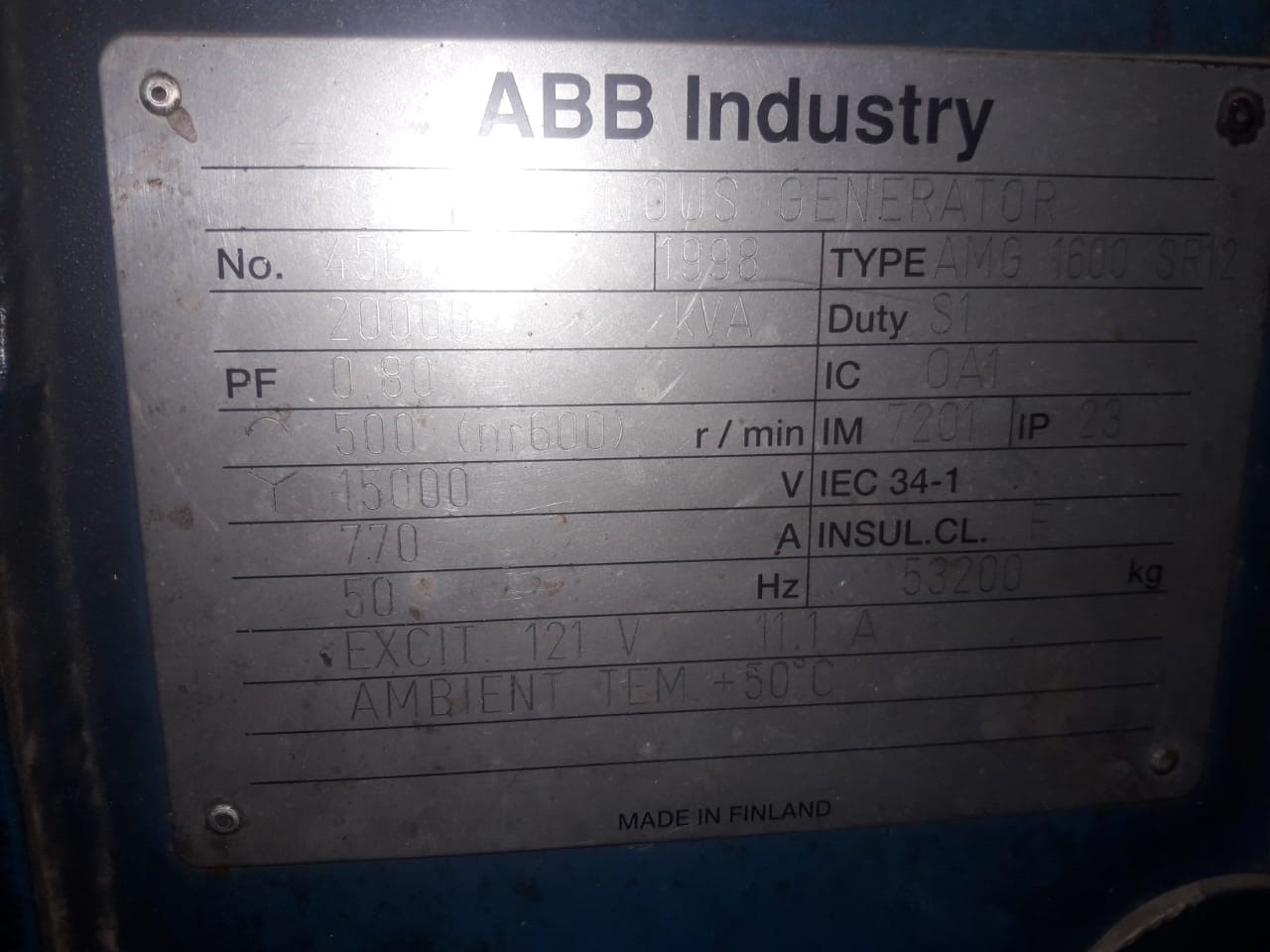

120MW Power Barge, 50Hz, Wartsila Engine Generator sets. YOM 1997. 8 X 15kV Wartsila Engines Model: Vaasa 18V46GD, 500rps. ABB Generator output 20,000 kVA, P.F. 0.8.

The Power Barge entered commercial operation in June 1999 has a capacity of 130 MW with a PPA contracted output of 110MW. The power barge was constructed in China with 8 Units of dual fueled Wartsila Engine as prime mover which fires on both Heavy Fuel Oil and as well Compressed Natural Gas ("CNG") to generate electricity through shaft connection to a ABB generator through 500 rpm speed. Electricity, 15kV at 50Hz, generated by the 8 Units of Wartsila Engine, ABB Generator is delivered to 2 ABB Main Step-up Transformers on board of the barge.

Black Start Generator and UPS

The power barge is equipped with an emergency diesel generator to ensure power supply to all essential plant support system when the plant is isolated from the grid to facilitate the starting of the plant from cold without back feed from the grid. The black start generator is connected with the Black Start Bus BFA-900. The power required for necessary auxiliary equipment to start two engine generators, namely Unit #2 and Unit #7 on fuel oil from cold condition is supplied from the black start bus.The plant is provided with 110V and 24V battery system for power back up in case of blackout. The battery systems are redundant and connected to a redundant battery charger.

Fuel Handling

Heavy fuel oil is currently in used. The heavy fuel oil is delivered directly to the storage tanks on board the barge by tank vessels. The tank vessel, carrying the heavy fuel oil, is moored alongside the power barge on the river side. The barge is able to store all the heavy fuel oil utilizing its 5 fuel oil storage tanks, each with a capacity of 500 MT.Although the engine supports fuel gas firing as primary fuel for operation, fuel gas is not in used since 2010 because of the fuel gas supply instability. A purpose built fuel gas compressor station was installed on site for fuel gas handling.

Layout and Construction

The Power Plant is permanently moored in SE Asia.

The power plant facility comprises of one floating power barge, gas compressor house / auxiliary equipment, office and storage buildings together with a comprehensive workshop.

Access to shore from the barge is enabled by gangways arranged to facilitate differences in sea water level. Power cables are arranged from one end of the power barge leading to an adjacent switch yard. Consequently, the power cables are not passing over the storage buildings inside the plant site. On the river side of the barge, there is a mooring arrangement and bunker station for the regular supply of fuel oil. The fuel oil pipes are arranged on the outside of the power barge and further distributed to the individual 5 storage tanks.

There is also a gas compressor station, where the natural gas is received via a pipe line from the LNG storage facility. This gas station compresses the natural gas pressure up to 360 bars before it is distributed through a single wall stainless pipe line to Commodore I before being consumed by the engine generators. The power plant is currently not operating on gas and has not been doing so since year 2010 due to shortage supply of gas.Each engine has a total running hours of less than 91,000 hours.

For more information and price contact Milt Fyre 503-351-9898 or milt@rmaglobal.com

>